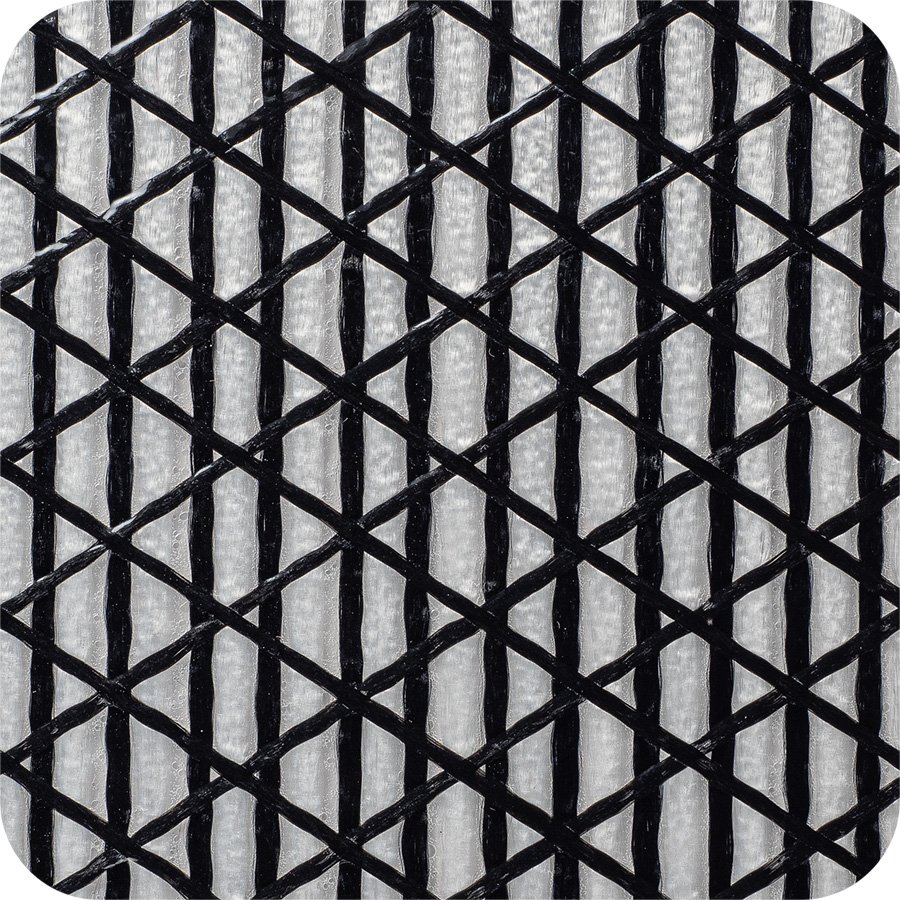

XRP ULTRA ARAMID

Technology

This year we introduce our new highmodulus line of XRP for bigger boatsand higher load cases that requiremore sail shape holding ability foryour more performance orientatedsailors. This line employs 100% highperformance warp fibers, botharamid and UPE, for superior stretchresistance which translates to boatspeed as the wind and loads increase.The UPE component adds toughnessand extra breaking strength over thelong haul. All fibers are black acrossboth the polyester and Ultra Aramidlines, hence different materials can beused on the same boat for differentsails, or for stepped constructionswithin individual sails

XRP Ultra Aramid 15

XRP Ultra Aramid 19

XRP Ultra Aramid 25

XRP Ultra Aramid

| Fabric ID |

Insert DPI Total Aramid UPE X 60°/.75" |

Film |

Weight SM oz gsm |

Width in cm |

| XRP Ultra Aramid 6 | 6,000 3,000 3,000 1,000 | 1.25 | 3.04 130 | 60 150 |

| XRP Ultra Aramid 10 | 10,000 4,000 6,000 1,000 | 1.50 | 3.74 160 | 60 150 |

| XRP Ultra Aramid 15 | 15,000 5,000 10,000 1,000 | 1.50 | 5.02 215 | 60 150 |

| XRP Ultra Aramid 19 | 20,000 10,000 10,000 1,000 | 1.75 | 5.49 235 | 60 150 |

| XRP Ultra Aramid 25 | 24,000 12,000 12,000 1,000 | 1.75 | 6.23 267 | 60 150 |

Energy-Efficient Manufacturing

Our textiles are produced at eco-friendly facilities powered by hydroelectric energy.

Our innovative manufacturing system eliminates expensive and energy intensive drying ovens, hot rooms for curing, and many other processes needed to laminate Nylon and Polyester with solvent-based adhesive.

We maintain stock in both the U.S. and Asia for better efficiency with our manufacturing partners and brands.